【Product Performance】

CUT-812 is a general purpose Cutting Oil specially configured for medium and high machinability metals under medium demanding operating conditions, suitable for medium and high difficulty cutting. The Cutting Oil has moderate viscosity and good cooling property, and is suitable for turning, milling, drilling, tapping and punching of copper, aluminum, iron and other metals.

【Product Parameters 】

Project | Typical Data | Test Method |

Appearance | Light yellow transparent | Visual inspection |

smell | Low odor Low odor | --- |

density(20℃) | 0.82~0.87 | Hydrometer |

Kinematic viscosity at 40°C (mm²/s) | 21~23 | GB/T 265 |

Flash point (°C) | >165℃ | GB/T 267 |

Mechanical impurities | Up to standard | GB/T 511 |

【Performance Characteristics】

★ Good Versatility: Formulated with a variety of special additives, it is non-corrosive to ferrous metals, copper, aluminum, and other non-ferrous metals, ensuring the brightness of the processed parts. Suitable for multiple materials and machining methods, reducing the variety of inventory products.

★ Good Lubricity: Possesses excellent extreme pressure and friction reduction properties, effectively ensuring the surface brightness of the processed parts and extending the tool life.

★ Excellent Cooling: Capable of removing the heat generated by intense friction during high-speed machining, reducing odor and component deformation to a minimal level.

★ Excellent Operability: Transparent in color, making it easy to observe the workpiece during machining. Low odor and low oil mist, making it easy for operators to adapt.

General Purpose Cutting Oils are essential lubricants in metalworking operations, designed to enhance tool life, improve surface finish, and optimize machining efficiency. Below are 4-6 key characteristics with technical data:

1. High Lubricity (Coefficient of Friction ≤0.15): These oils reduce friction between cutting tools and workpieces, minimizing heat generation. A coefficient of friction below 0.15 ensures smooth chip evacuation and extends tool life by up to 40% compared to dry machining.

2. Thermal Stability (Flash Point ≥180°C): With flash points exceeding 180°C, general-purpose cutting oils resist vaporization at high temperatures, maintaining consistent viscosity (ISO VG 22-68) even under heavy loads or prolonged use.

3. Corrosion Inhibition (Salt Spray Test ≥96 hours): Formulated with rust inhibitors, these oils protect ferrous and non-ferrous metals from oxidation, achieving 96+ hours in ASTM B117 salt spray tests without visible corrosion.

4. Multi-Metal Compatibility (pH 8.5-9.5): The balanced alkaline pH range (8.5-9.5) ensures safe use on steel, aluminum, brass, and other alloys without staining or chemical reactions.

5. Chip Flushing (Wetting Angle <30°): Low surface tension (<30° wetting angle) promotes rapid chip removal, reducing recutting and improving dimensional accuracy by ±0.02mm in precision operations.

6. Foam Control (ASTM D892 Foam Volume <50ml): Anti-foaming additives limit foam generation to under 50ml in standardized tests, ensuring uninterrupted fluid flow in high-pressure CNC systems.

【Range of Application】

● Suitable for copper, aluminum, iron and other metals turning, milling, drilling, tapping, punching and other processing technology.

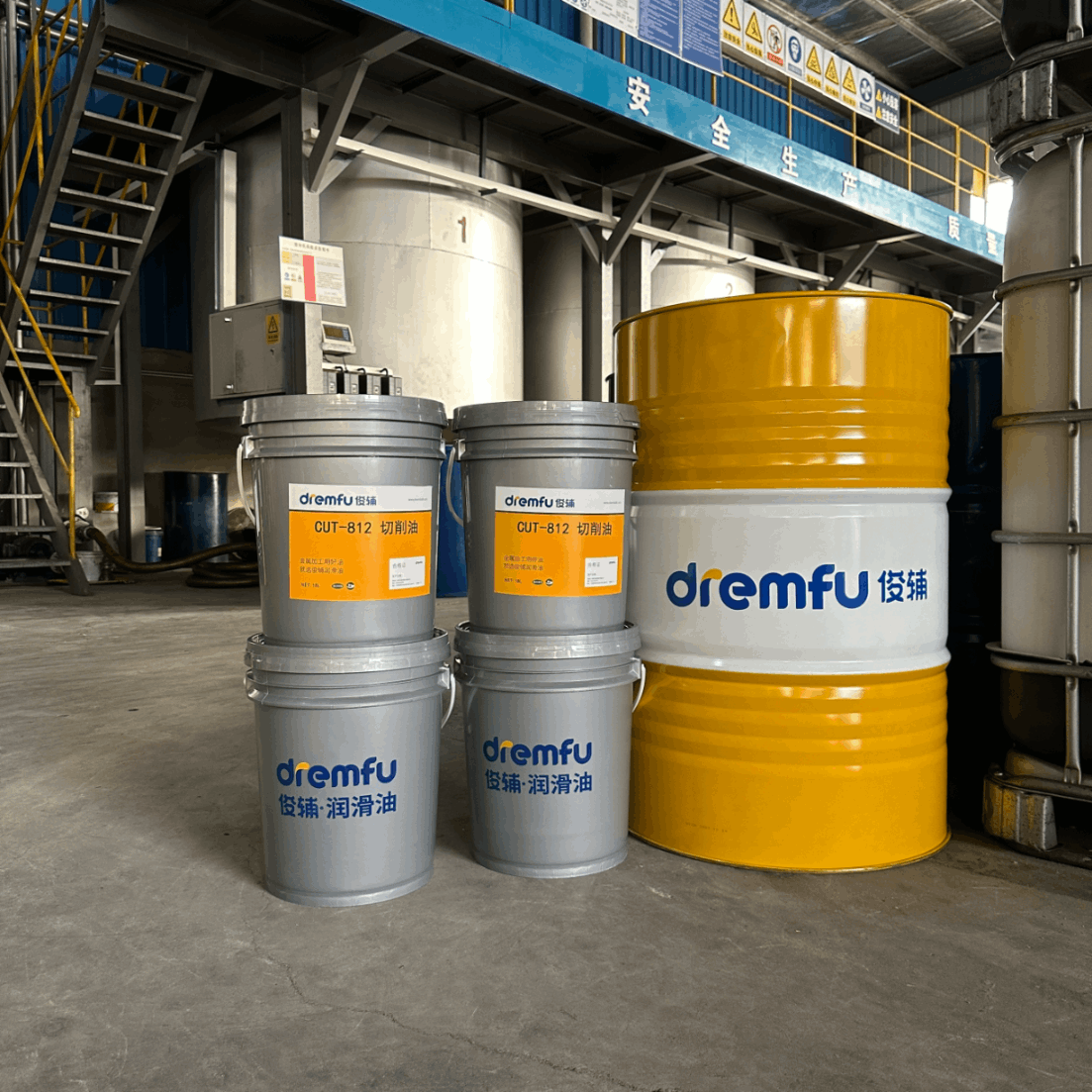

【Packaging Specifications】

18L/ plastic bucket, 200L/ large iron bucket.

Key Functions

Lubrication: By reducing friction between the cutting tool and the workpiece, these oils minimize heat generation and wear, thereby extending tool and workpiece life.

Cooling: The oil absorbs and dissipates the heat generated during the cutting process, preventing thermal deformation of the workpiece and ensuring dimensional accuracy.

Chip Removal: The lubricating properties of the oil help to evacuate chips smoothly from the cutting zone, reducing the risk of tool clogging and improving surface finish.

Corrosion Protection: The additives in the oil provide corrosion protection to the workpiece and machinery, ensuring longer tool life and reduced downtime.

Cleanliness: These oils help keep the working environment clean, minimize the accumulation of oil mist and reduce the risk of contamination.

Features

Versatility: These oils are formulated to be compatible with a wide range of metals, including ferrous and non-ferrous metals such as copper, aluminum and iron. This versatility makes them a cost-effective solution for shops that process a mix of different materials.

Lubricity: These oils have excellent lubricating properties, making them ideal for reducing friction and wear in high-speed, high-pressure machining operations. This helps achieve better surface finishes and longer tool life.

Cooling ability: They effectively dissipate heat generated during cutting, reducing the risk of thermal deformation and ensuring dimensional accuracy.

Transparency: Many universal cutting oils are transparent, making it easier for operators to observe the machining process and monitor the condition of the workpiece and tool.

Low odor and low mist: These oils are formulated to produce minimal odor and oil mist, making them more comfortable for operators to use and reducing the risk of respiratory problems.

Benefits

Improved surface finish: The lubricating properties of the oils result in a smoother, more refined surface on machined components.

Extended tool life: By reducing friction and wear, these oils help extend the life of cutting tools, reducing downtime and maintenance costs.

Increased productivity: Efficient cooling and lubrication increase machining speeds and feed rates, thereby increasing overall productivity.

Cost savings: Versatile oils can be used across a wide range of materials and machining operations, reducing the need for specialized lubricants and inventory costs.

Environmental benefits: Many universal cutting oils are biodegradable and contain fewer harmful chemicals, making them more environmentally friendly than traditional cutting fluids.

Applications

Turning: Whether you are machining a small diameter shaft or a large diameter component, these oils provide the necessary lubrication and cooling to ensure precision and quality.

Milling: During milling operations, the oil helps reduce friction between the milling cutter and the workpiece, resulting in smoother cuts and longer tool life.

Drilling: The lubricating properties of the oil help reduce the torque required to drill through the material, making the process faster and more efficient.

Tapping: These oils minimize friction and wear during tapping operations, ensuring accurate thread formation and longer tool life.

Punching: The oil helps reduce the force required to punch through the material, minimizing wear on the punch and die, and improving part quality.

Other Processes: General purpose cutting oils can also be used in other processes such as grinding, sawing and tapping, providing similar benefits in terms of lubrication, cooling and surface finish.