Our products are utilized across a range of industries

Providing effective lubrication solutions, expert technical support, and personalized one-on-one service to our customers

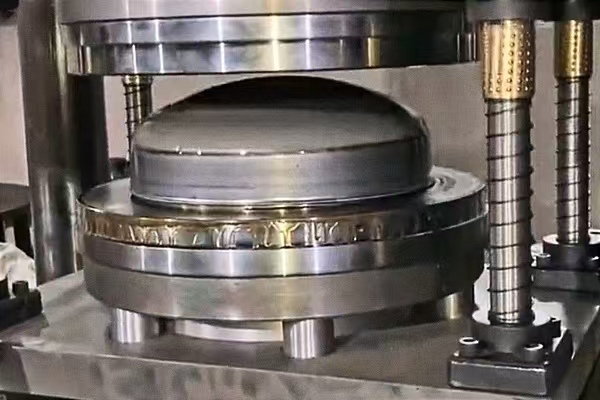

Dremfu stamping and drawing oils are classified into three main types: oil-based drawing oil, water-based drawing oil, and volatile stamping oil. These oils are used as lubricants in the metal stamping and forming processes and are typically applied in operations such as drawing, deep drawing, stretching, rolling, punching, spinning, pipe bending, and folding. Compared to other lubricants, drawing oils offer excellent extreme pressure lubrication, stability, and heat resistance, which can enhance processing efficiency and product quality.

The selection of drawing oil depends on factors such as the material, process, drawing difficulty, and subsequent cleaning requirements. Dremfu drawing oils are specifically named for different materials, such as aluminum drawing oil, stainless steel drawing oil, copper drawing oil, and titanium alloy drawing oil, among others. Different processes also have specific names for the oils, such as drawing oil, stretching oil, tube reducing oil, spinning oil, stamping oil, pipe bending oil, and shearing oil. Drawing oils are custom products with varying formulations depending on the difficulty of the stamping process. Unsure about which drawing oil to choose? Contact Dremfu Lubricants for professional recommendations!

Dremfu drawing oil is commonly used in various industries, including kitchenware, automotive manufacturing, air conditioning, firefighting, home appliances, aerospace, electronics, motorcycle parts, new energy, instrumentation, construction, transportation, mobile phone accessories, and cosmetics. Its broad application range spans over 30 industries.

Common Issues | Common Reasons | Solutions |

Workpiece streaking or cracking | The drawing oil's poor extreme pressure lubrication properties result in workpiece issues such as cracking, sintering, and scratching. | Switch to an extreme pressure type drawing oil. |

The product is difficult to clean | The drawing oil has poor degreasing properties, making it difficult to remove even with cleaning agents. | Switch to drawing oil that is easy to clean. |

The workpiece is rusting | The drawing oil's rust prevention capability between processes is insufficient, causing materials prone to rust, such as cold-rolled steel and iron, to develop rust soon after processing. | Switch to rust-resistant drawing oil. |

The non-ferrous metals are oxidizing and changing color | The drawing oil was not properly selected, leading to poor oxidation resistance. | Switch to oxidation-resistant drawing oil. |

High mold wear and frequent maintenance | The drawing oil's poor extreme pressure lubrication properties lead to significant wear between the workpiece and the mold. | Switch to drawing oil with good extreme pressure lubrication properties. |

Mold sticking and workpiece adhesion | The drawing oil's poor heat dissipation leads to increased mold temperature, which softens the workpiece, causing issues such as chip sticking and mold adhesion. | Switch to drawing oil with low viscosity and good heat dissipation properties. |

Strong, pungent odor | The raw materials used in the drawing oil itself have a strong odor. | Switch to drawing oil with a low odor. |

Dremfu drawing oil is formulated using branded base oils and various imported additives. It provides strong extreme pressure lubrication, preventing issues such as streaking, cracking, and sintering. It also protects molds and is easy to clean.

Dremfu drawing oil is customized based on various factors, including process, material, difficulty level, and subsequent cleaning requirements. The company provides one-on-one service with experienced professionals who first understand your needs and then recommend solutions, addressing various drawing lubrication challenges in depth.

Dremfu boasts a strong R&D team with over 10 technical engineers, equipped with an independent laboratory and comprehensive testing equipment. They offer custom solutions based on samples or desired effects and provide MSDS (Material Safety Data Sheet) and SGS (third-party) testing reports.

Dremfu operates a self-built facility of over 10,000 square meters, with a constant inventory of over 200 tons of raw materials. The company utilizes fully automated oil blending production lines with unlimited capacity. For regular products, orders can be shipped the same day, with some products available for shipment within 3 days.

Dremfu has established strategic partnerships with several international logistics companies, including Ocean Logistics, Datong Logistics, and Zhenhua Logistics. Additionally, Dremfu assigns dedicated personnel to oversee each shipment, ensuring timely delivery of every order.