【Product Performance】

CUT-526 Universal Fully Synthetic Cutting Fluid is a versatile, all-purpose synthetic metalworking fluid designed for multi-purpose use. It can process both ferrous metals and non-ferrous metals (such as cast iron, carbon steel, 45# steel, stainless steel, copper, and aluminum alloys of series 1-7). Formulated with high-quality imported additives, it provides exceptional lubrication and rust prevention properties, significantly extending the lifespan of cutting tools. It eliminates the hassle of frequent oil changes, and workpieces processed with this fluid do not require cleaning, thus greatly reducing labor costs. With low odor, low foam, and skin-friendly properties, it is environmentally friendly and easy to dispose of. Using this product can help alleviate many of your concerns!

【product parameters】

Testing Items | Parameters |

appearance of the base oil |

pale yellow, transparent |

density | 1.06-1.09g·cm³(20°) |

concentration | 35±1 |

PH value | 9±0.5 |

appearance of the diluted solution | light cyan, semi-transparent |

【usage method】

1. Before using this product, clean the machine, oil tank, or oil sump thoroughly. It is strictly prohibited to mix with other oils. Stir evenly before use.

2. Dilution ratio: Concentrate to water = 1:(1:20).

3. The concentration of the working fluid should not be lower than 5. Adjust the concentration of the working fluid appropriately according to different processing techniques, materials, and rust prevention requirements. For example: when processing stainless steel, the dilution ratio should be concentrate to water = 1:(1-10); when processing copper or aluminum alloys, the dilution ratio should be concentrate to water = 1:(1-20).

4. Note: For rust prevention, after 3 days, water can be added at a ratio of 10:1. After 7 days, water can be added at a ratio of 5 to 7 parts water to 1 part concentrate. After 10 to 15 days, water can be added at a ratio of 3 to 5 parts water to 1 part concentrate.

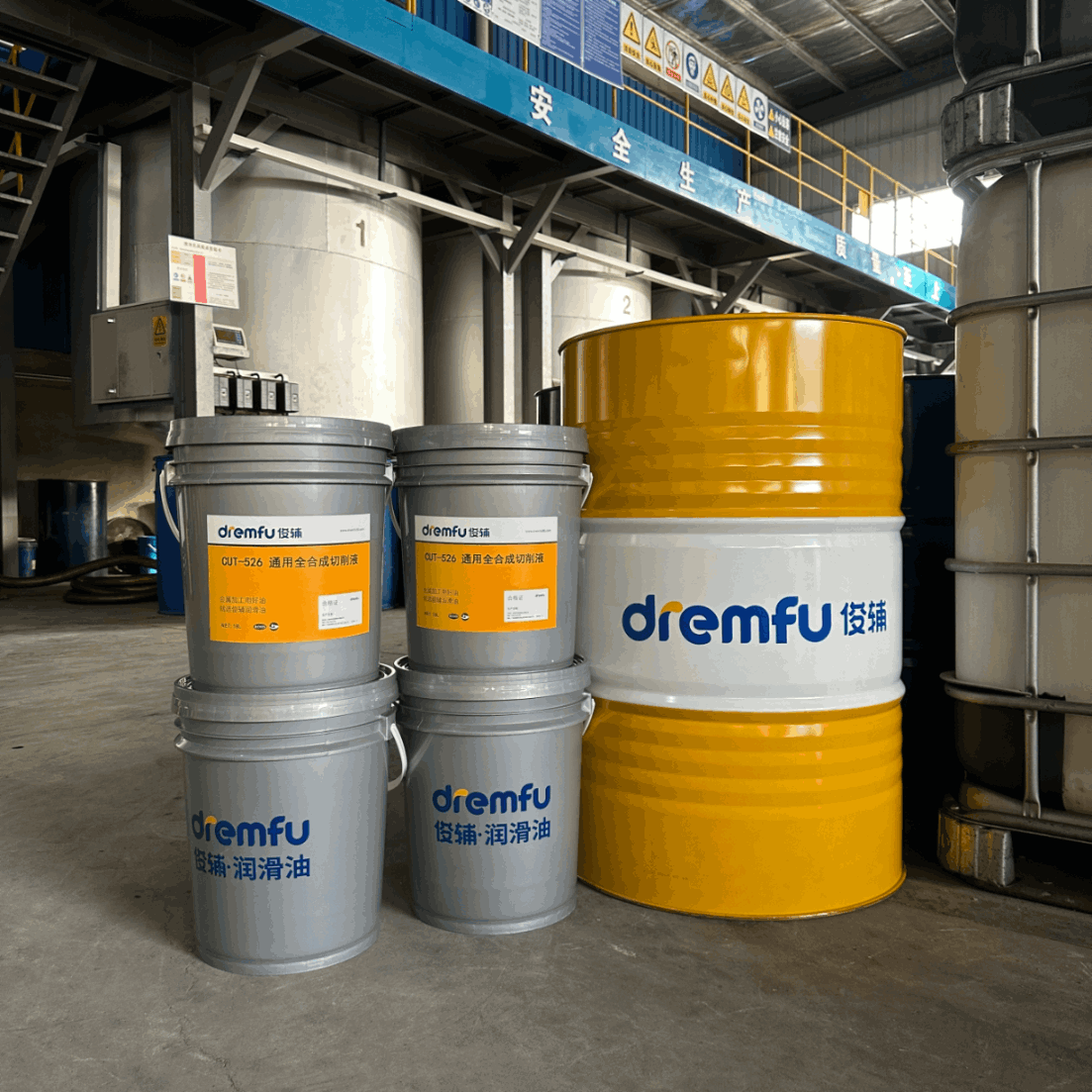

【packaging specifications】

18L per plastic drum, 200L per large iron drum

【Precautions】

1. Due to different production batches, there may be variations in the color of the cutting fluid, which does not affect normal use.

2. This product should be stored in a dry, cool, and well-ventilated warehouse. During storage and transportation, exposure to sunlight and rain should be avoided.