【Product Performance】

Synthetic Grinding Coolant is a high-performance, water-based lubricant designed to enhance machining efficiency and tool longevity. Unlike traditional oil-based coolants, it utilizes advanced synthetic additives to reduce friction, dissipate heat, and prevent corrosion. Its non-oily formulation minimizes residue buildup, ensuring cleaner work surfaces and improved workpiece quality. Ideal for precision grinding operations, it offers superior thermal stability, foam resistance, and environmental safety. Compatible with most metals, this coolant also inhibits bacterial growth, extending fluid life and reducing maintenance costs. A sustainable choice for modern manufacturing, it balances performance with eco-friendly attributes.

【Product parameters】

Testing Items | Parameters |

Appearance of the base oil | Golden yellow and transparent |

Density | 1.05-1.09g·cm³(20°) |

Concentration | 30±1 |

PH value | 9±0.5 |

Appearance of the diluted solution | Pale yellow and transparent |

【Usage method】

1. Before using this product, clean the oil tank or oil sump thoroughly. It is strictly prohibited to mix with other oils. Stir well before use.

2. Dilution ratio: Concentrate to water = 1: (1:10).

3. The concentration of the working fluid should not be lower than 5. Adjust the concentration of the working fluid appropriately according to different processing techniques, materials, and rust prevention requirements.

4. Note: For rust prevention, after 3 days, water can be added at a ratio of 10 times; after 7 days, water can be added at a ratio of 5 to 7 times; after 10 to 15 days, water can be added at a ratio of 5 to 3 times.

【Product Overview】

Synthetic Grinding Coolant is a full synthetic,water-based coolant engineered for high-precision grinding operations.It delivers exceptional cooling,low foam behavior,and superior lubrication—helping you reduce tool wear,improve surface finish,and maintain a cleaner working environment.Its environmentally safer formulation also minimizes residue buildup,keeping your workpieces and machinery in top condition.

【Key Features】

Thermal Stability:Maintains performance under high grinding temperatures,preventing overheating and surface distortions.

Low Foam&Clean Operation:Minimizes foam even under high pressure,leaving minimal residue.

Superior Lubricity:Reduces friction between grinding wheel and workpiece,driving down wear rate.

Corrosion Protection:Synthetic additives guard against rust and microbial build-up,extending coolant life.

Environmentally Friendly&Operator Safe:Water-based and free from heavy oil residues,making maintenance and disposal easier.

| Applications | |

Aerospace&Automotive components(bearings,turbine parts,transmission components) |

|

Tool&die finishing,where surface accuracy is critical |  |

| Electronics&Glass/Ceramics,especially for components needing ultra-clean finishes |  |

Medical Device Manufacturing,where hygiene and material compatibility are essential |  |

【FAQ】

Q1:Is this synthetic grinding coolant safe for use with all metals?

A:Yes.It is compatible with most metals—including steel,stainless steel,titanium and nonferrous alloys—offering corrosion protection and stable performance across materials.

Q2:How should I dilute and use the coolant?

A:Use concentrations suitable for your operation,typically in the range of 1:10 to 1:30 depending on grinding pressure,wheel speed,and material.Ensure the coolant is well mixed and the sump is clean before use.

Q3:How often should I replace or maintain the coolant?

A:Replace partially when performance drops(e.g.increased foam or odor).Monitor microbial growth;the coolant is designed to resist bacteria,but good filtration and tank cleanliness help extend life.

Q4:Can this coolant improve finish and reduce costs?

A:Absolutely.With better lubrication and cooling,the coolant helps reduce grinding wheel wear,lowers cycle times,and reduces waste—leading to overall cost savings.

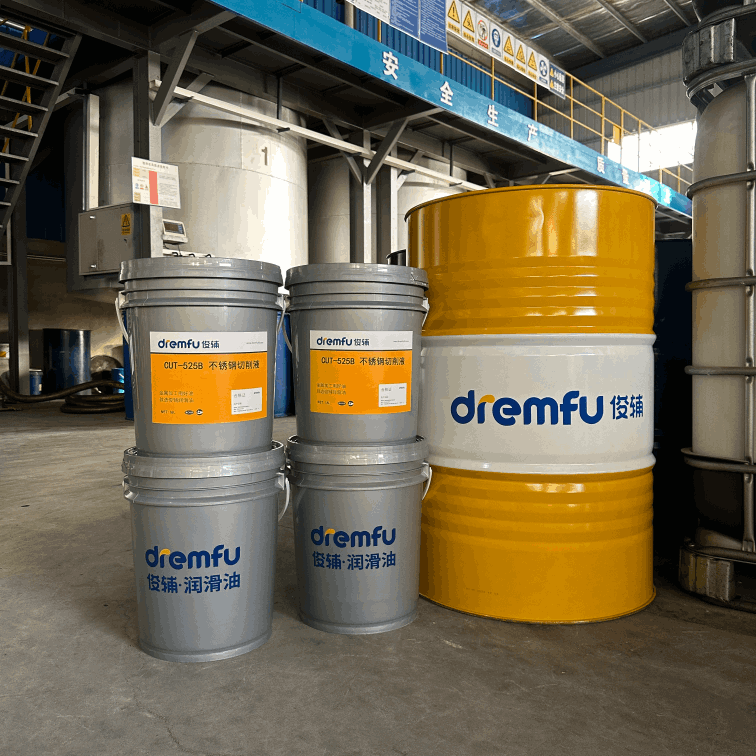

【packaging specifications】

18L per plastic drum, 200L per large iron drum

【Precautions】

1. Due to different production batches, there may be color variations in the cutting fluid, which does not affect normal use.

2. This product should be stored in a dry, cool, and ventilated warehouse, and exposure to sunlight and rain should be avoided during storage and transportation.

Looking to enhance your grinding processes with a high-performance Synthetic Grinding Coolant?Contact us now for a free sample,technical data sheet,or consultation.See how you can optimize tool life,productivity,and safety in your operations.