【Product Performance】

CUT-528L Zinc Alloy Specific Cutting Fluid (Microemulsion) is specially designed for processing zinc alloy materials. Formulated with high-quality imported additives, it boasts excellent lubrication and rust resistance. Odorless, low foaming, and gentle on the skin, it significantly prolongs tool lifespan. Move forward with confidence, and we’ll take care of all your worries along the way!

【product parameters】

Testing Items | Parameters |

appearance of the base oil | Golden yellow and transparent |

density | 0.89-0.92g·cm³(20°) |

concentration | 55±1 |

PH value | 9±0.5 |

appearance of the diluted solution | Light cyan color, semi-transparent |

【usage method】

1. Before using this product, thoroughly clean the machine, oil tank, or oil groove. Strictly avoid mixing with other oils, and ensure thorough stirring before use.

2. Dilution ratio: Concentrate : Water = 1 : (1:12).

3. The concentration of the working fluid should not be lower than 5. Adjust the working fluid concentration appropriately according to different processing techniques and rust prevention requirements.

4. Note: For rust prevention, after 3 days, water can be added at a ratio of 10 times the initial amount; after 7 days, water can be added at a ratio of 5 to 7 times the initial amount; after 10 to 15 days, water can be added at a ratio of 5 to 3 times the initial amount.

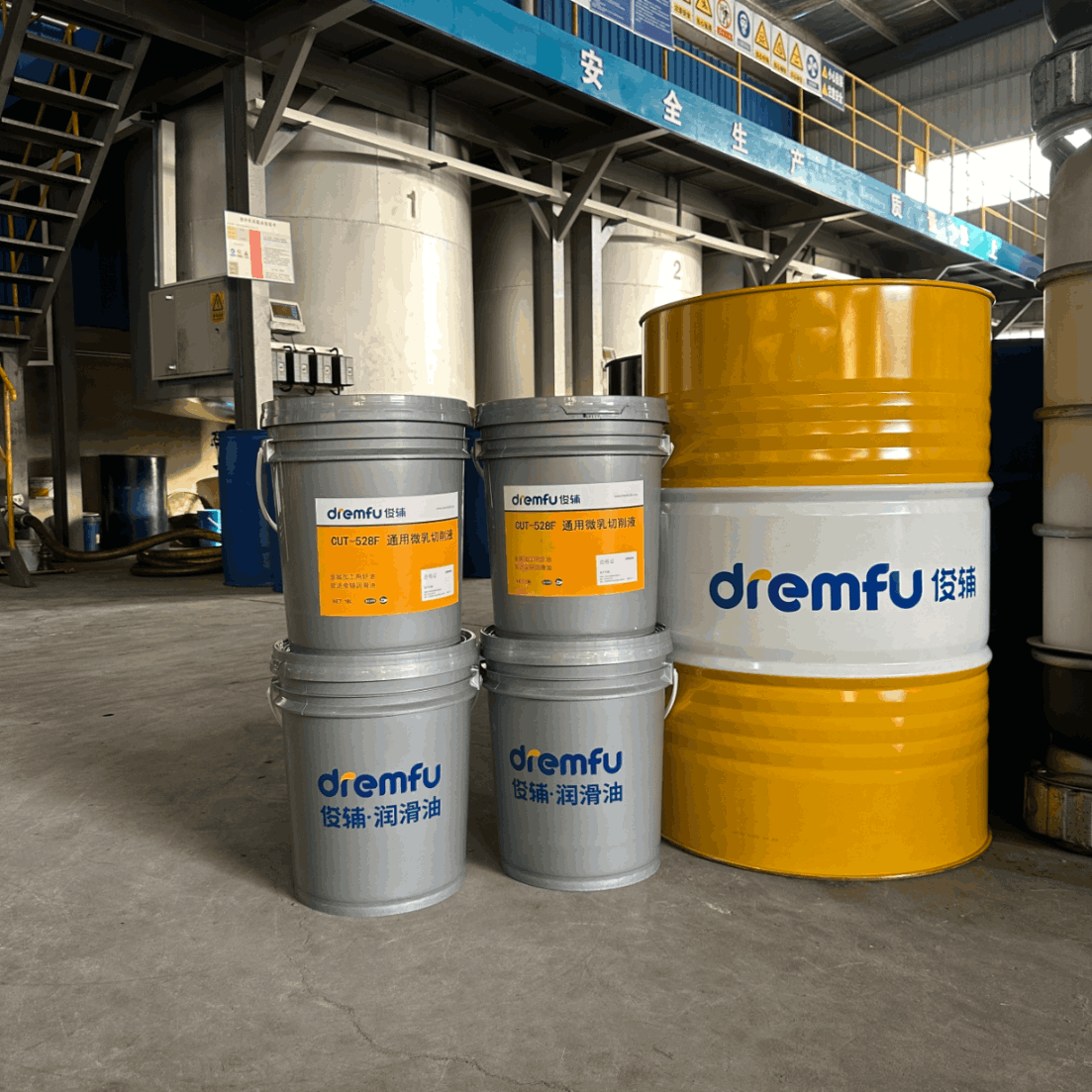

【packaging specifications 】

18L per plastic drum, 200L per large iron drum