2024-12-13 10:37:14

Introduction: In the field of metal processing, wire Drawing Oil plays a vital role. A high-quality Wire Drawing Oil can not only improve production efficiency, but also ensure product quality. So, how to judge the quality of wire Drawing Oil? This article will analyze it in detail from the following aspects.

1. Understand the basic properties of wire Drawing Oil

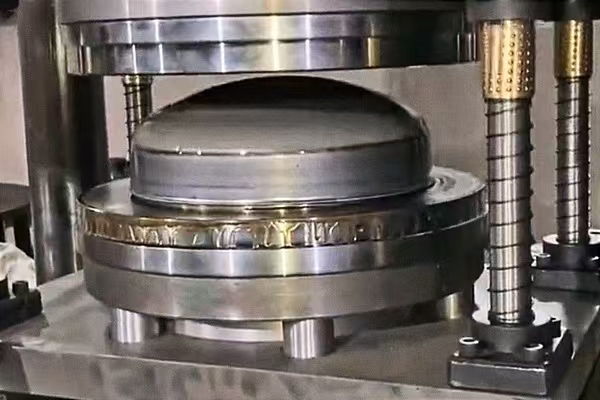

Lubricity: The main function of wire drawing oil is to reduce the friction between the metal wire and the die and reduce wear. Good lubrication performance can ensure the smooth progress of the wire drawing process and improve production efficiency.

Cooling: During the wire drawing process, the metal wire will generate a lot of heat. Wire drawing oil needs to have good cooling performance to reduce the temperature of the die and the metal wire, and prevent die wear and metal wire deformation caused by high temperature.

Rust resistance: Wire drawing oil should have certain rust resistance to prevent metal wire from rusting during processing.

Anti-foaming: Wire drawing oil is prone to foaming during use. Excessive foam will affect the lubrication effect and reduce processing quality. Therefore, wire drawing oil needs to have good anti-foaming performance.

Cleanliness: Wire drawing oil should have good cleaning performance, can effectively remove the oxide scale, dirt, etc. on the surface of the metal wire, and ensure the smooth progress of the wire drawing process.

Stability: During the storage and use of wire drawing oil, the performance should remain stable, and no stratification, precipitation, etc. should occur.

2. Methods for judging the quality of wire drawing oil

Appearance: High-quality wire drawing oil is transparent in color, without suspended matter and sediment. If the wire drawing oil is turbid in color, it means that it contains impurities and the quality is poor.

Odor: Wire drawing oil should have no irritating odor. If the odor is heavy, it may contain harmful ingredients, which will cause damage to human health and equipment.

Lubricity test: Soak the metal wire in wire drawing oil and observe whether a uniform oil film is formed on the surface of the metal wire. If the oil film is uniform, it means that the lubrication performance of the wire drawing oil is good.

Cooling test: Drop wire drawing oil on a hot metal sheet and observe the evaporation rate of the oil droplets. The faster the evaporation rate, the better the cooling performance.

Rust resistance test: Soak the metal wire in wire drawing oil, take it out after a certain period of time, and observe whether rust appears on the surface of the metal wire. If there is no rust, it means that the wire drawing oil has good anti-rust performance.

Anti-foaming test: Pour the wire drawing oil into a transparent container, stir and observe the foam generation. The less foam, the better the anti-foaming performance.

Cleaning test: Soak the metal wire in the wire drawing oil and observe whether the dirt on the surface of the metal wire is easy to remove. If it is easy to remove, it means that the wire drawing oil has good cleaning performance.

Stability test: Place the wire drawing oil in different environments such as high temperature and low temperature to observe whether its performance changes. If the performance is stable, it means that the wire drawing oil has good stability.

3. Purchase precautions

Choose a regular manufacturer: When purchasing wire drawing oil, you should choose products produced by regular manufacturers to ensure quality.

Understand product performance: According to production requirements, understand the various performance indicators of wire drawing oil and choose suitable products.

Pay attention to the price: The price is not the more expensive the better, and the right price can reflect the cost-effectiveness of the product.

After-sales service: Understand the manufacturer's after-sales service policy to ensure that problems encountered during use can be solved in a timely manner.

Sample test: Before purchasing, you can ask the manufacturer for samples for testing to verify whether the product performance meets the requirements.

4. Use and Maintenance

Correct use: According to the equipment and working environment, choose the type and amount of wire drawing oil reasonably.

Regular replacement: During the use of wire drawing oil, it will gradually age and deteriorate. To ensure the processing effect, the wire drawing oil should be replaced regularly.

Equipment cleaning: Keep the equipment clean to prevent dust, impurities, etc. from entering the wire drawing oil and affecting the use effect.

Storage conditions: Wire drawing oil should be stored in a cool, dry and ventilated place to avoid direct sunlight.

5. Summary

To judge the quality of wire drawing oil, a comprehensive evaluation is required from multiple aspects. Mastering the above methods, I believe you will be able to buy high-quality wire drawing oil that suits your production needs. At the same time, during use, pay attention to maintenance and maintenance to ensure that the wire drawing oil plays the best effect and improve production efficiency and product quality.

In the metal processing industry, the quality of wire drawing oil is directly related to production costs and product quality. Therefore, when purchasing and using wire drawing oil, be sure to pay attention to quality and follow the methods and precautions described in this article.