【Product Performance】

CUT-528F High-Quality Universal Microemulsion Cutting Fluid is an upgraded version developed based on CUT-528. Formulated with premium imported additives, it offers enhanced lubrication and rust prevention capabilities, as well as better biostability. It can process a variety of materials such as copper, iron, aluminum, stainless steel, etc., eliminating the hassle of frequent oil changes, significantly reducing labor costs, and greatly extending tool lifespan. It is the ideal choice for processing various hardware materials.

【product parameters】

Testing Items | Parameters |

appearance of the base oil | Orange-yellow and transparent |

density | 0.87-0.92g·cm³(20°) |

concentration | 70±1 |

PH value | 8.7±0.5 |

appearance of the diluted solution | Light cyan color, semi-transparent |

【usage method】

1. Before using this product, thoroughly clean the oil tank or oil groove. Strictly avoid mixing with other oils, and ensure thorough stirring before use.

2. Dilution ratio: Concentrate : Water = 1 : (1:20).

3. The concentration of the working fluid should not be lower than 5. Adjust the working fluid concentration appropriately according to different processing techniques, materials, and rust prevention requirements. For example: For stainless steel processing, the dilution ratio can be adjusted to: Concentrate : Water = 1 : (1-10); For copper and aluminum processing, the dilution ratio can be adjusted to: Concentrate : Water = 1 : (5-20).

4. Note: For rust prevention, after 3 days, water can be added at a ratio of 10 times the initial amount; after 7 days, water can be added at a ratio of 5 to 7 times the initial amount; after 10 to 15 days, water can be added at a ratio of 5 to 3 times the initial amount.

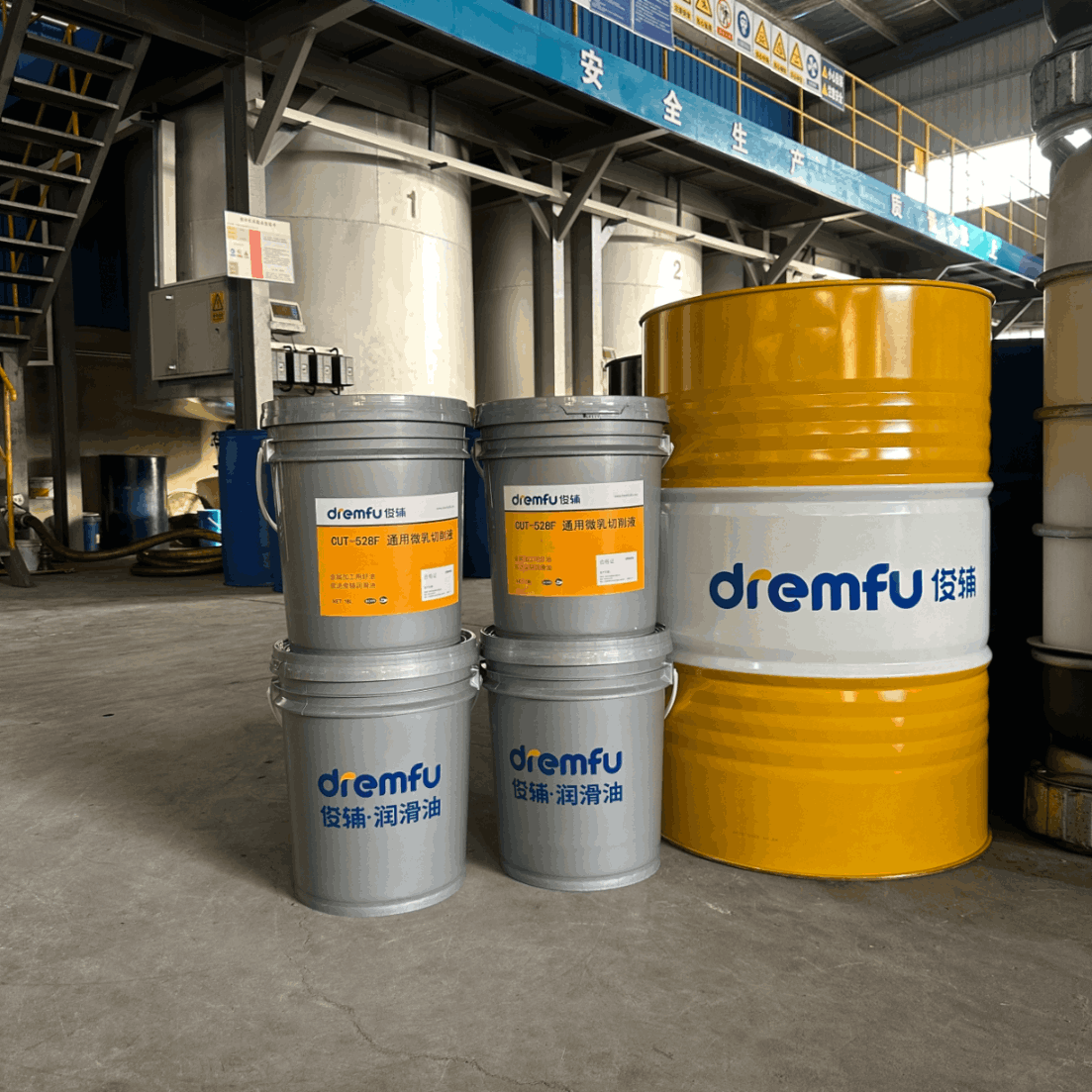

【packaging specifications】

18L per plastic drum, 200L per large iron drum

![]() High-Quality Universal Microemulsion Cutting Fluid CUT-528F.pdf

High-Quality Universal Microemulsion Cutting Fluid CUT-528F.pdf