【Product Performance】

CUT-813GY Stainless Steel Tapping Oil is a premium-grade cutting fluid specifically engineered for tapping,drilling,reaming,and threading applications in stainless steel and other high-strength alloys.Stainless steel is notoriously difficult to machine due to its toughness and tendency to cause tool sticking or chip welding.CUT-813GY is formulated to overcome these challenges by offering superior lubrication,cooling,and anti-wear properties.The result is smoother machining,longer tool life,and improved surface finish.

By reducing friction and dissipating heat effectively,this tapping oil is widely recognized as a reliable solution for manufacturers working in industries such as automotive,aerospace,shipbuilding,heavy machinery,and precision engineering.

【Product Parameters 】

Project | Typical Data | Test Method |

Appearance | Light ellow transparent | Visual inspection |

Smell | Low odor | --- |

density | 0.82~0.87 | hydrometer |

Kinematic viscosity 40°C (mm²/s) | 21~23 | GB/T 265 |

Flash point (°C) | >165℃ | GB/T 267 |

Mechanical impurities | Qualified | GB/T 511 |

【Performance characteristics】

Product Features:

★ Lubricity: Possesses excellent extreme pressure and friction reduction properties, with superior anti-seizure function, effectively ensuring the surface brightness of the processed parts and extending tool life.

★ Excellent Cooling: Capable of removing the heat generated by intense friction during high-speed machining, reducing odor and component deformation to minimal levels.

★ Excellent Operability: Transparent in color, making it easy to observe the workpiece during machining. Low odor and low oil mist, making it easy for operators to adapt.

【Range of Application】

● Used for tapping, drilling and other processing of stainless steel and alloy steel.

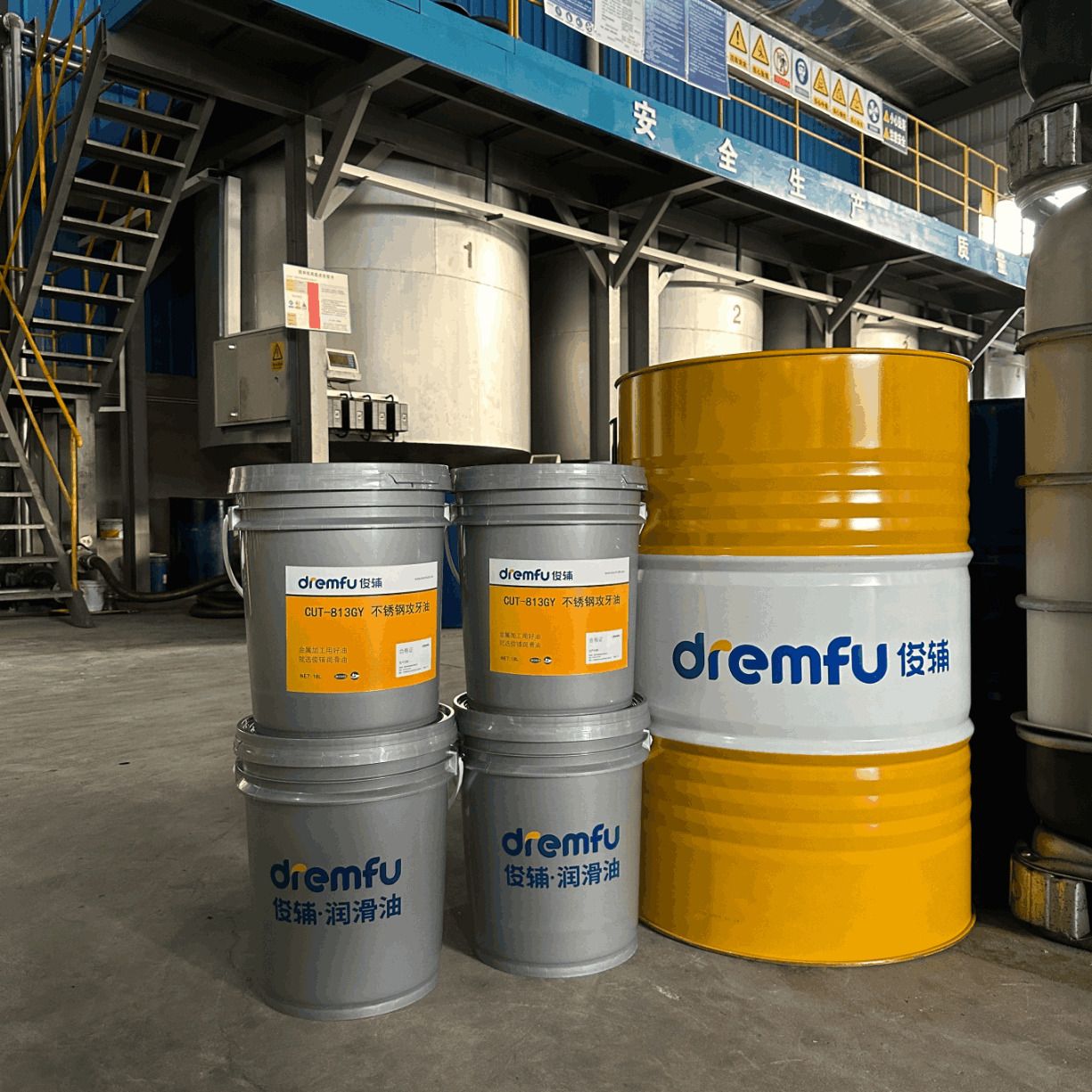

【Packaging Specifications】

18L/ plastic bucket, 200L/ large iron bucket.

![]() Stainless Steel Tapping Oil.pdf

Stainless Steel Tapping Oil.pdf

【Key Benefits of CUT-813GY Stainless Steel Tapping Oil】

*Outstanding Lubrication Performance

Forms a durable oil film under extreme pressure conditions,reducing friction between the cutting tool and the workpiece.

Prevents galling and thread damage during tapping.

Extended Tool Life

Reduces wear on taps,drills,and reamers,minimizing downtime and replacement costs.

Independent tests show tool life can be extended by up to 50%compared to standard cutting oils.

*Effective Cooling Properties

Quickly removes heat generated in stainless steel machining.

Prevents thermal deformation,maintaining workpiece dimensional accuracy.

*Anti-Sticking and Anti-Chip Welding

Prevents chips from welding to the cutting edge,a common issue when machining stainless steel.

Ensures smoother chip evacuation,reducing tool breakage risks.

Clean and Safe Formula

Chlorine-free and sulfur-free composition.

Low odor,safer for operators,and compliant with environmental standards.

【Applications】

CUT-813GY Stainless Steel Tapping Oil is highly versatile and can be applied across a wide range of machining operations,including:

Tapping and threading stainless steel bolts,pipes,and fittings

Drilling operations in alloy steel and carbon steel components

Reaming and boring precision holes in heavy-duty metals

Machining heat-resistant steels used in aerospace or power generation

CNC machining centers,tapping machines,and drill presses